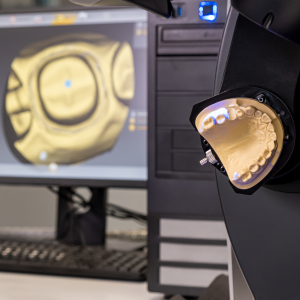

In recent years, the advancement of technology has transformed the dental industry, and laboratories have been no exception. In particular, the use of computer-assisted design (CAD) has revolutionized the way prostheses and other dental devices are designed and manufactured. However, many dental laboratories still face challenges in the adoption and optimization of this technology. This is where having a CAD design partner becomes a strategic decision to maximize efficiency, quality and competitiveness in the market.

Technical advantages of having a CAD design supplier

- Precision and consistency in designs

CAD design offers a level of precision that is difficult to match by manual methods. Dental laboratories face high standards of accuracy in the creation of prostheses, implants and aligners. With a specialized CAD design provider, it is guaranteed that each designed part meets the exact requirements and offers consistency throughout production, reducing the risk of errors and the need for subsequent adjustments.

- Quick adaptation to market demands

The dental world is dynamic, with new trends and technologies constantly emerging. A laboratory that works independently may have difficulty adapting quickly. However, by having a partner in CAD design, the laboratory can be up to date with the latest innovations and take advantage of the best practices in each project. This not only allows you to stay competitive, but also offer advanced and customized products for customers.

- Reduction of human errors

Although the experience and skill of the technical staff in a dental laboratory are crucial, human errors are inevitable. The use of CAD technology minimizes these inaccuracies, and working with a specialized partner ensures that designs are supervised and optimized by experts, thus reducing the margin of error. Fewer errors means less additional costs and less time spent on corrections, which improves laboratory efficiency.

- Optimization in the manufacture of dentures and dental devices

A CAD design partner not only delivers ready-to-print or mill files, but also optimizes designs so that they are better suited to the specific manufacturing processes of each laboratory. This means that the designs will be adjusted to the available machines and materials, maximizing the efficiency of the workflow.

Commercial benefits of having a CAD design partner

- Savings in costs and production times

One of the main benefits is the significant reduction in operating costs and production times. An experienced supplier can develop optimized designs faster than an internal team, allowing the laboratory to focus on other critical areas, such as customer service and the expansion of its service portfolio. This saving in time and money can be directly reflected in greater profitability.

- Improved team productivity

When a dental laboratory outsources its CAD design, it allows its internal team to focus on tasks that require personal attention, such as completing, adjusting, and supervising the quality of dentures. This frees up time and resources, which in turn increases the overall productivity of the laboratory. A more focused and productive team can handle more cases, offering better results to customers.

- Ability to handle a greater volume of work

A dental laboratory that handles large volumes of orders needs to ensure that its processes are efficient and scalable. A CAD design partner can take on a significant part of the workload, allowing the laboratory to accept more orders without sacrificing quality. In this way, a laboratory that would otherwise be limited by its internal capacity can expand its business in a sustainable way.

- Increased end customer satisfaction

The precision, speed and efficiency that is obtained from working with a CAD design supplier not only benefits the laboratory, but also the customers. Patients who receive better adjusted and higher quality dental devices will be more satisfied, which not only improves the reputation of the laboratory, but also increases loyalty and attracts new customers through recommendations.

Cases of application in dental laboratories

Here are examples where a CAD design provider has been key to improving processes in dental laboratories:

Personalized dental prostheses: Laboratories that work with complex dental restoration cases have reported that the accuracy and customization of the CAD designs, managed by an expert partner, has significantly improved the quality of the prostheses delivered.

Invisible dental aligners: The design of aligners is a process that requires high precision to obtain effective results. With an expert CAD design supplier, laboratories can create custom aligners with great precision, improving delivery times and the satisfaction of orthodontists and patients.

Implants and support structures: In many dental laboratories, implants require highly customized structures to fit the unique anatomy of each patient. An expert company in CAD design can optimize these processes to ensure a perfect fit from the first time.

Precision, efficiency and adaptability are essential for success, and having a CAD design partner not only brings technical advantages, such as precision and error reduction, but also commercial, allowing dental laboratories to save time, reduce costs and improve customer satisfaction. If you manage a dental laboratory and are considering how to optimize your processes, collaborating with a CAD design expert may be the boost you need.

If you are looking for ways to improve your designs and manufacturing processes, contact us to explore how we can help you take your dental laboratory to the next level.